In 1946, an inspired couple, Dotty and David Dalquist (recently returned from World War II), decided to start a modest kitchenware business inspired by Scandinavian tradition, under the name Nordic Ware.

The venture began in their basement in Minneapolis, United States, with a small investment of $500 — all their savings. Drawing from their cultural heritage, they produced Scandinavian kitchen tools: the Rosette iron, the Krumkake iron, the Platte Panne pan, and the Ebelskiver pan.

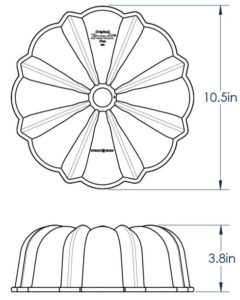

Without a doubt, Nordic Ware’s most famous product today is the Bundt® pan, found in over 70 million households around the world.

The success began modestly with a revisited kougelhof — traditional ceramic molds used to bake the cake known in Eastern European countries as Kougelhopf.

David, along with his engineer, designed a cast aluminum pan and gave it the name Bund, the German word meaning both “ring” and “federation”, to which he added a “T” and pan, the English word for mold.

NORDIC WARE, INVENTOR OF THE BUNDT AND OWNER OF THE WORD BUNDT®,

IS TODAY A POWERFUL BRAND KNOWN WORLDWIDE.

With a dose of perseverance, the brand still proudly manufactures the vast majority of its products in Minneapolis, United States. From 2 employees to more than 350, Nordic Ware is now distributed in over 50 countries around the world.

A family-owned company with three generations involved, Nordic Ware continues to grow and innovates each year with new utensils and mold designs.

THE BUNDT® CAKE: OFTEN IMITATED BUT NEVER EQUALLED

Molds crafted from cast aluminum and guaranteed for life:

– Lighter than cast iron

– Less fragile than ceramic

– Clear material composition, unlike silicone which may contain traces of peroxide — harmful particles that can migrate into food from 160°C

– Oven-safe (up to 204.4°C / 400°F) and freezer-compatible

– Cast aluminum has properties very similar to aluminum: lightweight, an excellent conductor of heat, and durable, it ensures fast, responsive, and even baking.

A meticulous design tailored to the unique shape of each mold, allowing for the integration of highly detailed patterns while ensuring perfect cake baking: soft on the inside and crispy on the outside.

The thickness of the cast aluminum varies within the mold; it is thicker around edges and patterns — areas with less batter — to prevent overbaking and drying out of the cake.

Exterior: made of cast aluminum for optimal heat conductivity, with two coats of paint in attractive colors.

Interior: three nonstick layers + a nonstick coating specially designed for sugar — different from the one used by competitors or standard pans, which is typically meant for cooking meat.

COLLECTIONS THAT FOLLOW THE RHYTHM OF THE SEASONS!